Subproject 3

Fraunhofer Institute for Mechanics of Materials (IWM)

TP 3

-

Microstructure-based modelling of adiabatic shear band formation in HSB

During the production of sheet metal components using high-speed blanking (HSB), the formation of adiabatic shear bands (ASB) can be observed within the shear zone depending on the selected process parameters and the material. The focus of the proposed sub-project is the development of numerical modelling approaches to describe the formation and propagation of ASB in HSB as well as the microstructure development within the ASB. By combining thermo-mechanical and microstructural simulation approaches and taking experimental data into account, a fundamental understanding of the mechanisms relevant to ASB formation is to be developed and a model of ASB formation in HSB for the materials under consideration is to be developed, implemented, validated and applied to real processes. This will make it possible to better analyse, evaluate and understand the HSB process and support process optimisation. Statements about the forming ASB and the expected properties of the cut edge are made possible.

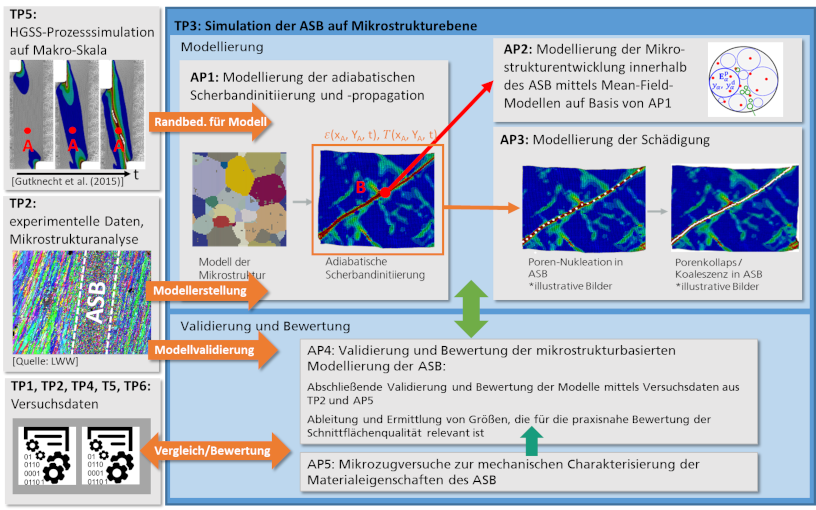

The figure shows the planned work packages. These are assigned to a modelling part and a validation and evaluation part. The modelling part contains three work packages, with each work package focusing on a specific modelling issue. These are then coupled unilaterally, i.e. results from WP1 are transferred to WP2 and WP3, while results from WP2 flow into WP3 if necessary. In the validation and evaluation part, micro tensile tests are carried out in WP5 to mechanically characterise the ASB or the material in the environment of the ASB. In WP4, a final validation and evaluation of the microstructure-based ASB modelling is carried out.

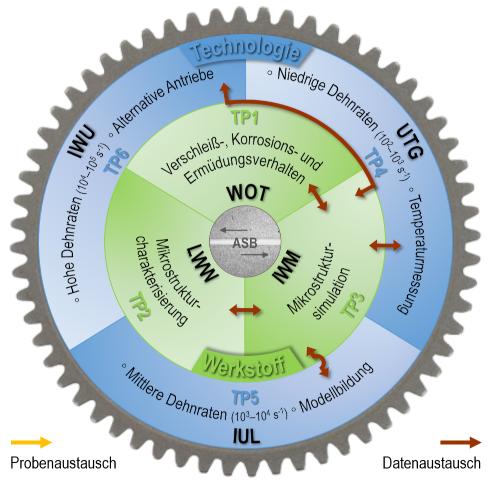

Networking diagram of TP3 with the most important sample and data exchange paths