Home

DFG Research Unit 5380

"Functional surfaces through adiabatic high-speed processes: Microstructure, mechanisms and model development - FUNDAM³ENT"

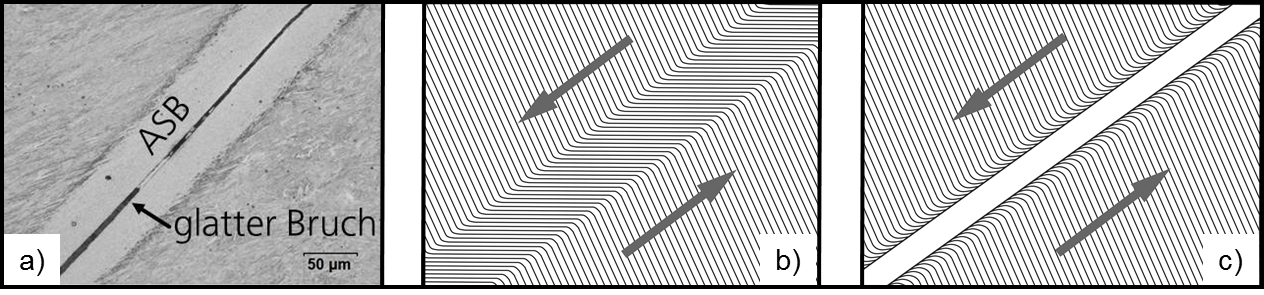

High-speed blanking (HSB) is an economically and ecologically interesting alternative to conventional cutting processes such as normal, fine or laser cutting. For high-strength and ultra-high-strength steels in particular, but also for light metals, HSB harbours great potential in terms of producing cut surfaces that can be used directly as functional surfaces without further mechanical, thermal or thermochemical post-processing steps. This is due to the fact that, depending on the material and the process parameters, adiabatic shear bands (ASB) can form in the HSB, in which the material separation then takes place (Fig. 1).

Figure 1:

a) Light microscope image of an ASB in 20MnB5. The failure of the material in the centre of the shear band leads to a very smooth fracture surface. b) and c) Schematic representation of the microstructure of the two adiabatic shear band types in metallic materials due to previous dynamic shear deformation: b) deformation shear band, c) transformation shear band. _

Figure 1:

a) Light microscope image of an ASB in 20MnB5. The failure of the material in the centre of the shear band leads to a very smooth fracture surface. b) and c) Schematic representation of the microstructure of the two adiabatic shear band types in metallic materials due to previous dynamic shear deformation: b) deformation shear band, c) transformation shear band. _

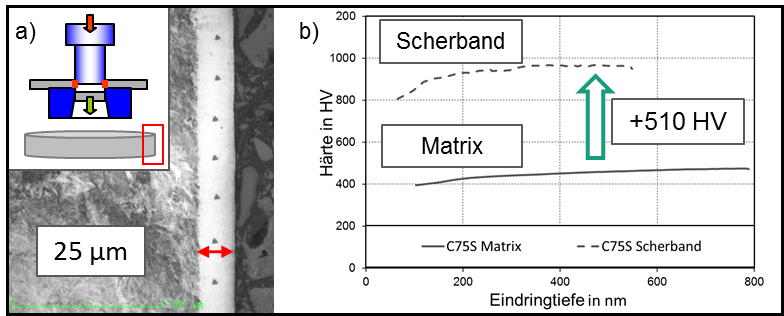

The resulting cut surfaces are characterised by high hardness, low edge indentation and low roughness and have virtually no burr (Fig. 2). To date, however, there has been a lack of fundamental understanding of the mechanisms that lead to the formation of ASB in HSB. This, in turn, is essential in order to be able to utilise the extraordinary cut surface properties described. The FUNDAM³ENT research group is therefore working in an interdisciplinary network to investigate the material and process-related factors influencing the formation of ASB in HSB.

Figure 2:

a) Cutting edge of a slug made of hardened steel with homogeneously formed ASB according to the HSB. b) Hardness in the shear band and in the base material (matrix)

.

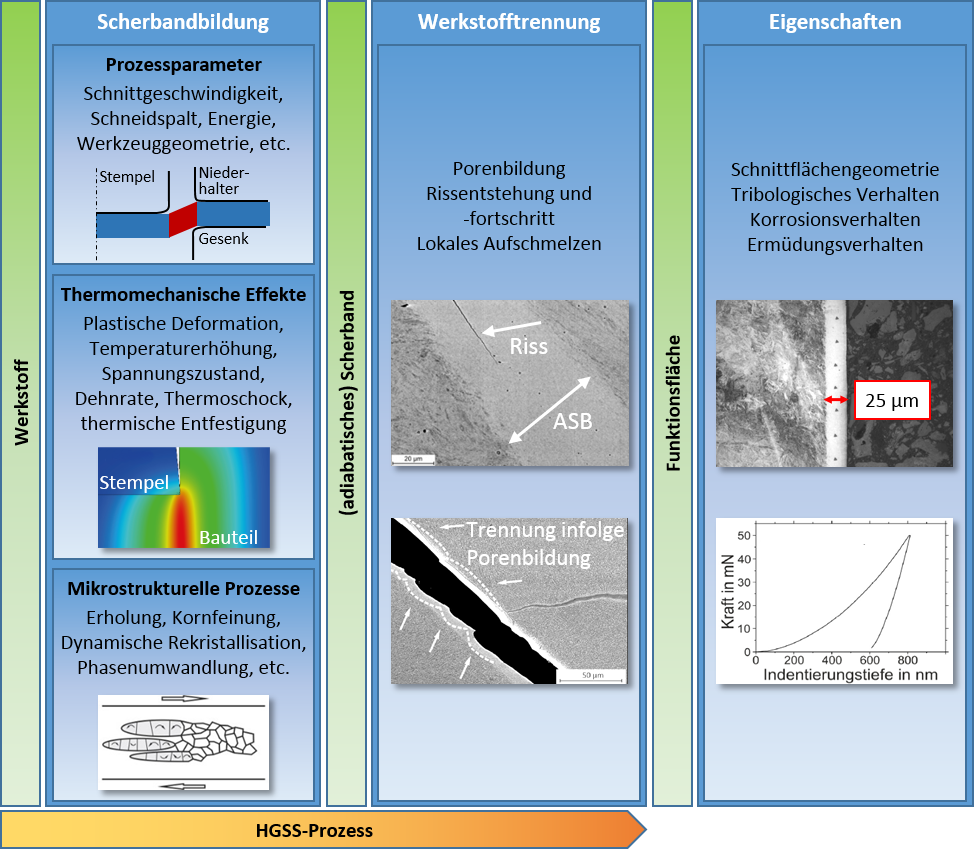

The overarching aim of the research group is to develop a model based on materials science and process technology that describes shear band formation in HSB as comprehensively as possible, i.e. for different materials and in a wide range of process parameters. This is to be achieved by pooling expertise from the fields of materials science, materials engineering and production engineering. Important research questions that will be examined in more detail in the research group include, for example, the influence of various structural components and the deformation history on the tendency to shear band formation or the question of whether ASB can also be produced in materials with good thermal conductivity, such as aluminium. Research is also being carried out into the extent to which the strain rate in the HSB process determines the microstructure, geometry and properties of the shear bands and whether the melting or recrystallisation temperature of a material influences ASB formation and the resulting microstructure. Extensive experiments in different strain rate ranges of the HSB (10²-10⁵ s⁻¹) generate comprehensive process knowledge on the one hand and are the basis for a sound understanding of the microstructural effects occurring in the shear band on the other. This is supported by multi-scale simulation methods at microstructural and process level. Systematic investigations of the material behaviour of HSB cut surfaces under tribological, corrosive and cyclic mechanical loads enable the relationships between the blanking process, the microstructure and the resulting cut surface properties to be examined (Fig. 3).

Figure 3:

Key aspects of the HSB process that are taken into account when developing models within the FOR.

Figure 3:

Key aspects of the HSB process that are taken into account when developing models within the FOR.