Subproject 2

Materials Science Group (LWW)

TP 2

-

Thermomechanical characterization and microstructural analysis of the interaction of shear bands with elements of the microstructure

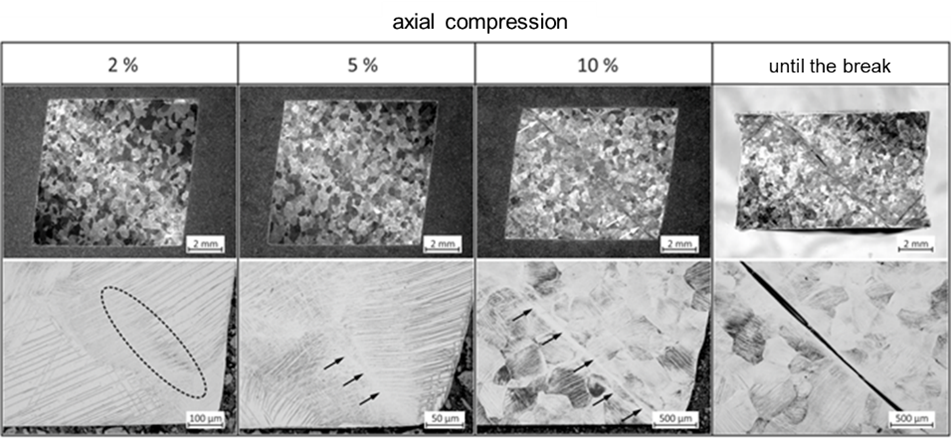

Adiabatic shear band formation occurs as a deformation process in metallic materials particularly at high deformation rates. Shear band formation is characterized by energy dissipation during plastic deformation, which is associated with a local temperature increase that leads to local softening and, finally, to an increasingly pronounced localization of the subsequent deformation. A detailed understanding of shear band formation is interesting from the point of view of materials science, experimentally challenging and also highly relevant from a technological point of view, especially in the context of high-speed blanking (HSB). A key objective of this research subproject 2 is to investigate the influence of different initial microstructures on the formation and growth of different types of shear bands in unalloyed and low-alloyed steels, respectively, as well as in a non age-hardenable aluminum alloy. This involves the targeted use of stopped, highly dynamic experiments in order to document different stages of shear band formation and propagation and subsequently to systematically characterize the adiabatic shear bands in terms of microstructure. Figure 1 shows as an example light microscopic images on transverse sections of compression shear specimens compressed to different extents. In this specimen geometry (cylindrical base shape with slightly inclined faces), shear bands are preferentially formed at the edge of the faces and grow diagonally through the specimen in the direction of the shear stresses superimposed by the primary compressive load.

Figure 1. Preliminary work on stopped tests during the deformation of so-called cylindrical compression-shear specimens made of a titanium alloy. In the light microscopic images, the various stages of shear band formation and growth up to the failure of the specimen can be seen.

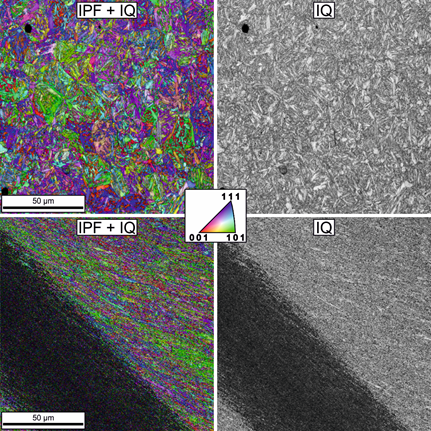

The subproject 2 furthermore aims at developing criteria for the evaluation of the shear tendency of the investigated materials during HSB, with a special focus on strain rate sensitivity, strength and thermal conductivity of the materials. In particular, the aim is to understand the relationships between the initial microstructures and the resulting shear band properties. The focus is not only on the macroscopic investigation of the mechanical behavior but also on the microstructural and micromechanical characterization of shear bands, with additional consideration of the influence of different stress states. Figure 2 exemplifies that microstructural investigations (especially in the scanning electron microscope, SEM, using electron back-scatter diffraction, EBSD) allow the analysis of microstructural changes during adiabatic shear band formation in steel materials. This allows the identification of the highly deformed transition regions adjacent to the actual adiabatic shear band, whose microstructure ultimately determines the properties of the functional surfaces explored in the research group.

Figure 2. Preliminary work on a C75 steel with martensitic-bainitic microstructure. The results of EBSD measurements in the SEM (orientation information and image quality as a qualitative measure of local distortions) allow a comparison of the undeformed base material (top) and the heavily deformed zone in the immediate vicinity of the shear band (bottom). The shear band itself shows such strong deformations that an even higher resolution analysis in the TEM is required.

A comprehensive, systematic characterization of microstructural gradients below the HSB interfaces is required to accurately describe the functional cutting surfaces produced by HSB and its properties, and conditions for tailoring well-defined surface properties will be identified. Consequently, a significant contribution will be made to the central research goals of the Research Unit by the development of a clear understanding of the relevant microstructural mechanisms – from the initiation of an adiabatic shear band, via its growth and interaction with microstructural features, to the functional surface generated during HSB.

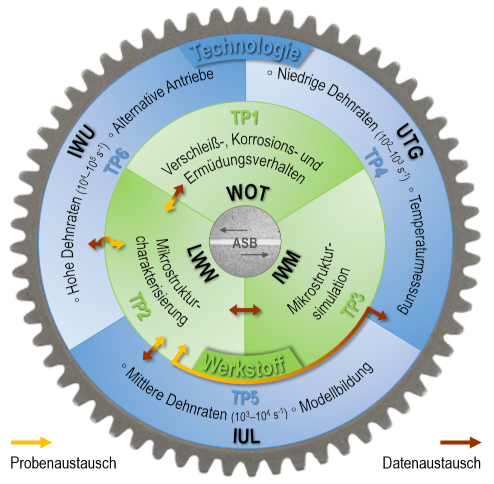

Networking diagram of TP2 with the most important sample and data exchange paths